SCREED ACCESSORIES

Motor-side Axle Extension: Enables screeding on either side of the motor. It is typically best to keep the system on the right side of the pour, however, the extension provides flexibility when needed, such as situations where there are obstructions on both sides.

Wall Plugs: Allow operation next to a wall. Two options are available, 6-inch and 18-inch, and easily thread to the screed’s handle end to create the additional length necessary for challenging areas.

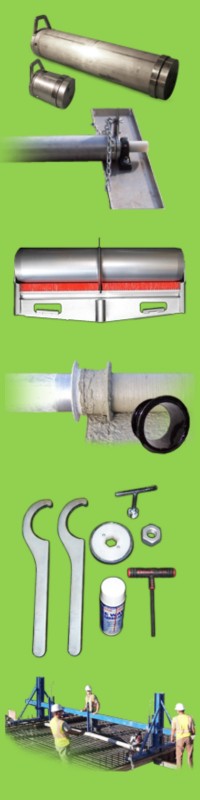

Riser Wheel Rings: Elevate the Lightning Strike system 1/8-inch above the pour. With the additional height, patching jobs become faster and easier, while excessive stress is taken off the unit to reduce premature wear.

Wet Screed Shoe: Determines proper height and speed on sloped pours. On side-by-side wet pours, the shoe also eliminates extra work by allowing the handle end to float across the top of the previous pour.

CV Joint: Sets the desired pitch. Ideal for applications where a peak is required such as crowns, cambers or if the slab is running to a drain, the CV Joint can be tightened for flatter results or loosened for greater pitch.

Form Runner: Reduces the system’s wear on metal forms. By simply sliding on the tube, the Form Runner can be easily positioned to ride between the screed rotation and the form.

Accessory Tote: Provides convenient storage for tools and accessories. Additionally, the tote contains 6-way lubricant, two spanner wrenches, a T-bar wrench and extra black and white caps.

Adjustable Curb Runner: Enables the system to ride on top of an existing curb. Greatly reduces finish time on projects by eliminating the need to set forms and perform time- and labor-intensive hand-screed work.

Trolley System: Revolutionizes cambered pours and simplifies bridge deck crowns for custom pours at a lower cost. Fully adjustable to any height, the Trolley System clears obstacles as it finishes pours as wide as 38 feet at a fraction of the cost incurred by conventional equipment.

Pervious Joint Cutter: Rolls control joints in pervious concrete to prevent cracking in weak areas. Custom cutters are available upon request to suit various thickness requirements.

Cross Roller: Offers a means to achieve solid compaction in every pour. To ensure best compaction results, the hollow tube can be filled with water to desired weight, up to 125 pounds.